Current Location:Home > News Center > Company News > DaZu CNC Intelligent Manufacturing Solution Helps Breakthrough in High end Manufacturing of Consumer Electronics

Current Location:Home > News Center > Company News > DaZu CNC Intelligent Manufacturing Solution Helps Breakthrough in High end Manufacturing of Consumer Electronics

The electronic information industry is an important pillar industry of China's national economy. On July 21st, the National Development and Reform Commission officially issued the "Several Measures to Promote the Consumption of Electronic Products", launching a series of policy measures to promote the consumption of electronic products and promote the recovery of consumer electronics demand.

Since the third quarter of this year, new products such as Huawei and Xiaomi have been released one after another, sparking a consumer boom. The domestic mobile phone market is gradually recovering, driving the accelerated recovery of the upstream and downstream prosperity of the consumer electronics industry chain.

In September, Huawei released its latest flagship product - the Huawei Mate 60 series, which is the world's first mass smartphone to support satellite calls. It features a "long lost" metal integrated body (or aluminum alloy material); In October, Xiaomi held its 2023 new product launch event, and the Xiaomi 14 Pro launched a titanium special edition. The phone's middle frame is made of 99% pure titanium and high-strength aluminum alloy material precision composite.

01 Aluminum Alloy - Common Materials for Consumer Electronics

The lightweight, strong, corrosion-resistant, and conductive properties of aluminum alloy make it an ideal material for consumer electronics terminal products. Aluminum alloy is mainly used for phone cases, tablet cases, laptop cases, computer host cases, and frame structures. Aluminum alloy is prone to thermal deformation and surface oxidation during the processing, which requires high demands on cutting tools and processing environment.

02 Titanium Alloy - Consumer Electronics Trend Materials

2023 is the first year for the application of titanium alloy in the consumer electronics industry, and mainstream mobile phone manufacturers are introducing titanium alloy materials one after another.

Titanium alloy has advantages such as high strength, lightweight, high temperature resistance, and durability, and is mainly used in the frame, back cover, and frame structure of terminal products such as smartphones. The overall yield rate of titanium alloy phone frames is about 30% -40%, much lower than the 80% of aluminum alloy frames; And the processing time is long, about 3-4 times that of aluminum alloy. As a typical difficult to process material, titanium alloy has poor processability and high processing difficulty, which has become a pain point for 3C manufacturers to improve product output and yield.

DaZu Machine Tool can provide high-performance and efficient machining for users in industries such as consumer electronics based on different material characteristics and specifications of components, and offer a complete set of CNC intelligent manufacturing solutions.

The scheme adopts high-speed and high rigidity spindle, adaptive machining technology, and high-precision, high rigidity, and high feed processing methods, combined with tool monitoring and dynamic feedforward control, temperature feedback control, surface fine treatment technology, as well as intelligent detection, automatic loading and unloading functions, to automatically and continuously complete the composite processing of aluminum alloy, titanium alloy and other materials in one clamping,Meet the requirements of high-precision, lightweight, and aesthetically pleasing consumer electronics products, and improve user production efficiency and product qualification rate.

This issue focuses on the consumer electronics industry

Processing of key components and structural parts

Recommend four efficient and high-precision tools for everyone

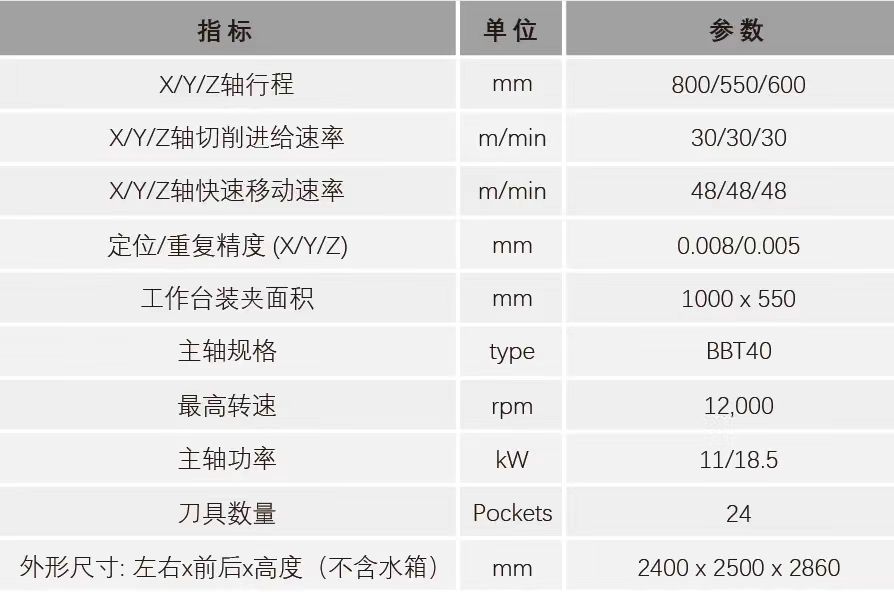

It has more advantages in application scenarios with high precision requirements and rapid mass production, and is a model with high productivity and cost-effectiveness. Especially suitable for high-speed aluminum parts

Efficient processing.

A universal machine model that can efficiently and flexibly process complex parts, with a wide range of applications, and can achieve "one machine, high efficiency, and multiple capabilities", effectively meeting market changes and user needs

Production demand.

Combining high rigidity and high response with high speed and precision, it is a model of high-speed and high-precision machining. Directly connected high-speed spindle and high rigidity structure of moving parts,

Achieve 100% spindle performance.

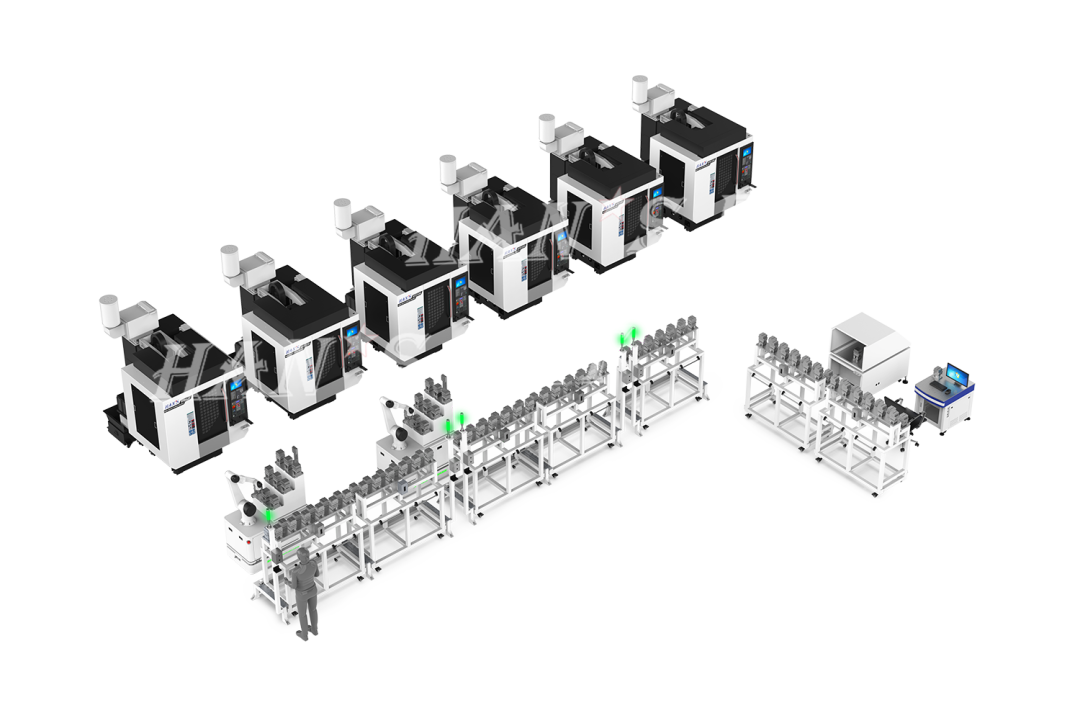

A highly efficient, integrated, automated, and intelligent automated production line tailored to customer needs, capable of fast and flexible scheduling, and highly suitable for small batches

Multi variety hardware product processing.