Current Location:Home > News Center > Company News > [Industry Case] The demand for new energy continues to rise, and DaZu Machine Tool empowers the three electric systems to improve both in quantity and quality!

Current Location:Home > News Center > Company News > [Industry Case] The demand for new energy continues to rise, and DaZu Machine Tool empowers the three electric systems to improve both in quantity and quality! Case Study of New Energy Vehicle Industry

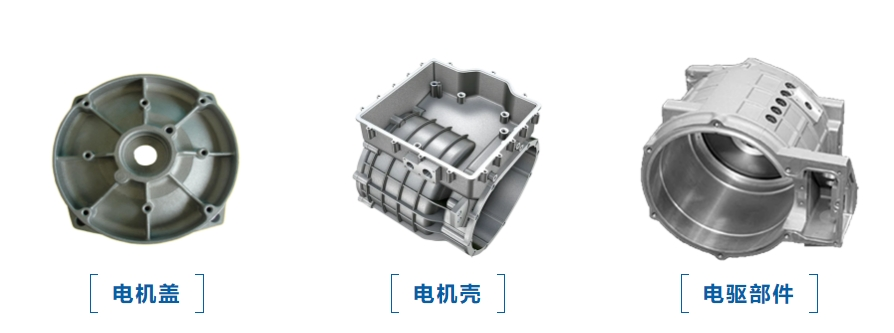

The three electric system is the core component and powertrain of new energy vehicles, and is the most important criterion for measuring whether a car has hardcore strength. The "three major components" of new energy vehicles, consisting of "motor, electronic control, and battery", require high-end CNC machine tools with high precision, high speed, and high yield for customized and efficient processing.

Recently, the General Office of the State Council and relevant departments of the State Council have successively issued a series of policies on new energy vehicles, clarifying the need to consolidate and expand the development advantages of new energy vehicles, and strongly support the high-quality development of the new energy vehicle industry.

According to data from the China Association of Automobile Manufacturers, the penetration rate of new energy passenger vehicles in China reached 27.6% for the whole year of 2022, and the penetration rate of new energy vehicles will continue to increase rapidly in the future.

According to data from the China Association of Automobile Manufacturers, in July 2023, the production and sales of new energy vehicles in China reached 805000 and 780000 respectively, an increase of 30.6% and 31.6% year-on-year, with a market share of 32.7%. From January to July 2023, the production and sales of new energy vehicles reached 4.591 million and 4.526 million respectively, an increase of 40% and 41.7% year-on-year, with a market share of 29%.

Under the dual support of national policies and market demand, the development of the new energy vehicle industry maintains a high level of momentum and the penetration rate continues to increase.

The extensive application of new technologies, materials, and structures has put forward new requirements for the manufacturing process of new energy vehicles. The three electric system is the core component and powertrain of new energy vehicles, and is the most important criterion for measuring whether a car has hardcore strength. The "three major components" of new energy vehicles, consisting of "motor, electronic control, and battery", require high-end CNC machine tools with high precision, high speed, and high yield for customized and efficient processing.

Against the backdrop of rapid iteration in the manufacturing process of new energy vehicles, high-end CNC machine tools, as important equipment in automotive production lines, are accelerating their localization journey and expanding their application scenarios.

DaZu Machine Tool is an automation expert in the field of machine tools. With expertise in the manufacturing of key components for different types of new energy vehicles, DaZu Machine Tool has developed a series of models and key processes, providing users with a complete set of intelligent manufacturing solutions and one-stop, full process efficient services, promoting the simultaneous improvement of the quantity and quality of the three electric systems, and consolidating the foundation for the high-speed and high-quality development of the new energy industry.

This issue focuses on new energy vehicles

Processing of key components in the three electrical systems

Recommend two efficient processing tools for everyone

HT1300 High Speed Drilling and Attacking Center

X/Y/Z axis travel: 1300/650/450mm

The HT1300 high-speed drilling and tapping center integrates drilling, tapping, milling and other processing, and is widely used in industries such as automotive key components, 3C, small mold processing, medical equipment, etc. It has great advantages in the processing of small and medium-sized plate, shell and disc parts such as new energy vehicle motor end caps, transmission end caps, and vehicle terminals.

The overall structure of the machine is a C-shaped structure, and the bed body is made of Mihanna casting technology and undergoes complete aging heat treatment to eliminate stress, resulting in high rigidity and stable precision of the machine tool. All casting structures have undergone finite element analysis, fully meeting the needs of high-speed response cutting for machine tools. The X/Y/Z axis guide rails are all supported by ball line rails, which have high rigidity, low friction, strong seismic resistance, and can achieve better dynamic responsiveness.

The excellent performance of HT1300, including high precision, high efficiency, and high reliability, can effectively meet the processing technology requirements for rapid iteration and upgrading of the three electric systems in new energy vehicles.

LW1150 Vertical and Horizontal Machining Center

X/Y/Z axis travel

1100/Vertical 650/Horizontal 650/Vertical 500/Horizontal 600mm

The Da Zu Machine Tool LW1150 Vertical and Horizontal Machining Center is mainly used for multi-faceted composite machining of large parts in industries such as automotive key components, 5G communication, and mechanical manufacturing. Linear and circular interpolation cutting can be used to complete machining processes such as milling, boring, drilling, expanding, reaming, and tapping. Very suitable for processing parts such as gearboxes, motor housings, and electronic control housings for new energy vehicles, including housing, plates, disks, and shells.

The LW1150 is highly automated, equipped with dual spindle and hydraulic rotary shaft, and can complete five sided machining with one clamping, reducing multiple clamping errors. The vertical and horizontal dual BT40 spindle structure design allows for flexible switching of machining methods, efficiently meeting the precision cutting needs of high hardness materials.

As a powerful tool with a wide range of applications and multiple processing categories, LW1150 can flexibly and efficiently process various complex shaped components in the field of new energy vehicles, balancing universality and high efficiency, bringing doubled value to users.

With the rise of the domestic new energy vehicle industry, it has provided abundant development soil for the upstream industry, and key automotive component manufacturing enterprises and their upstream process enterprises will usher in new development opportunities.

Ten years of quality witness, Dazu Machine Tool continuously strengthens key core technology research and development, fully unleashes the advantages of domestic brand localization services and process applications, accelerates the journey of domestic substitution, and helps user enterprises such as key component manufacturing of new energy vehicles improve their "intelligence" and efficiency upgrading.