Resource centre

By browsing through frequently asked questions (FAQ) related to the topic and obtaining technical information about the product.

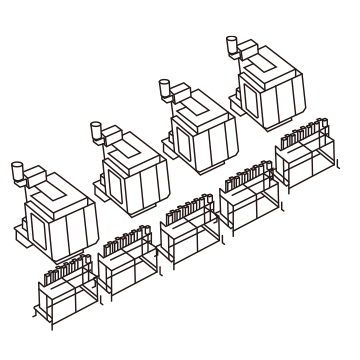

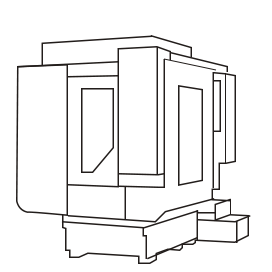

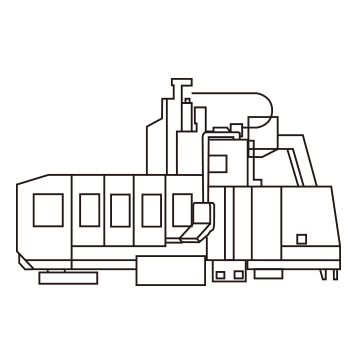

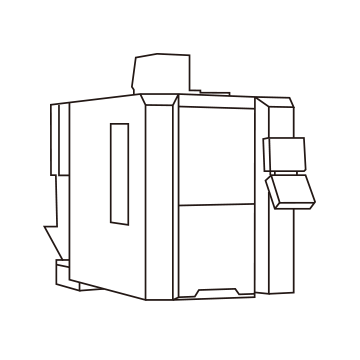

Gantry machining center

Application Industry

Can be widely used for machining of products in the fields of automation equipment,mold,medical,electronic,mechanical,automotive,shipping

Standard configuration

MITSUBISHI M80

Arm type tool magazine

Semi-enclosed protective cover

Centralized automatic lubrication system

Heat exchanger

Tool kit

Foundation bolts&pads

Screw type chip conveyor

Link type chip conveyor + protable chip bucket

Optional configurations

SINUMERIK 828D /FANUC

The 4th axis

Side milling head

Five axis head

Coolant through spindle system(CTS)

Tool setter

RENISHAW probe

Tool breakage detection system

Oil cooler of spindle

| Item | Description | Unit | HL1613 | HL2015 | HL3018 |

|---|---|---|---|---|---|

| Working range | X/Y/Z-axis stroke | mm | 1700/1400/700 | 2100/1650/700 | 3000/1800/800 |

| Spindle nose to table (standard) | mm | 150-850 | 150-850 | 180-980 | |

| Gantry width | mm | 1420 | 1650 | 1850 | |

| workbenches | Table size | mm | 1700*1200 | 2200*1400 | 3200*1500 |

| Max table load | kg | 3500 | 4000 | 8000 | |

| T-slot size | mm | 7-22*157.5 | 7-22*192.5 | 10-22*150 | |

| Spindle | Spindle drive mode | direct connection | direct connection | direct connection | |

| Spindle speed | rpm | 12000 | 12000 | 12000 | |

| Max torque | N.m | 118 | 118 | 118 | |

| Rated torque | N.m | 52.5 | 52.5 | 52.5 | |

| Max power | kW | 18.5 | 18.5 | 18.5 | |

| Rated power | kW | 11 | 11 | 11 | |

| Tool changing system | Tool shank type | BT40 | BT40 | BT40 | |

| Tool magazine capacity | Pockets | 24 | 24 | 24 | |

| Tool magazine type | Arm type | Arm type | Arm type | ||

| Maximum tool diameter | mm | 80/150 | 80/150 | 80/150 | |

| Maximum tool length | mm | 350 | 350 | 350 | |

| Maximum tool weight | kg | 8 | 8 | 8 | |

| Feed | Cutting feed rate(X/Y/Z) | m/min | 10/10/10 | 10/10/10 | 5/5/5 |

| Rapid traverse(X/Y/Z) | m/min | 16/16/16 | 16/16/16 | 8/10/10 | |

| Positioning accuracy (X/Y/Z) | mm | 0.012/1000 | 0.012/1000 | 0.012/1000 | |

| Repeatability(X/Y/Z) | mm | 0.008/1000 | 0.008/1000 | 0.008/1000 | |

| Mechanical parameters | Mechanical dimensions | mm | 5000*4000*3800 | 6000*4300*3850 | 8100*4600*3800 |

| Machine weight | kg | 12000 | 16000 | 26000 |