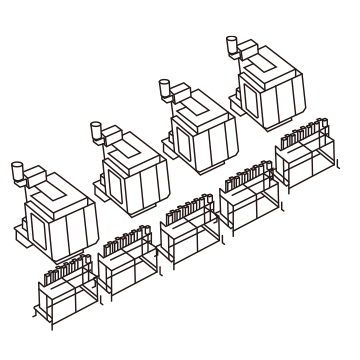

Automated solutions

Application Industry

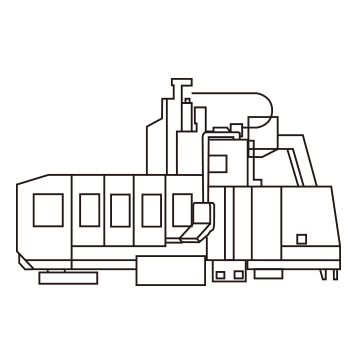

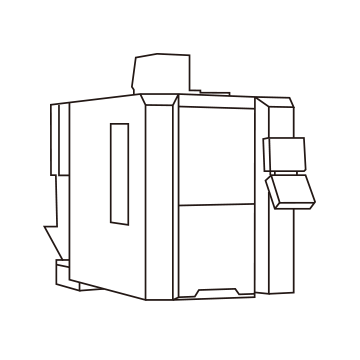

Focusing on the machining industry, we provide one-stop solutions for a series of products including feeding mechanism, compound robot, ground rail robot, etc. Through zero-point quick change, RFID, intelligent control, 0T technology, we realize the automation, digitization and intelligence of machine tool loading and unloading and supporting equipment, which can provide customers with a strong guarantee for improving quality, reducing costs and increasing efficiency. It integrates: basic labor

JiChuangBao specializes in the machining industry, providing a one-stop solution that includes a series of products such as feeding mechanisms, composite robots, and ground-track robots. By leveraging quick-change technology, RFID, intelligent control, and IoT, it achieves automation, digitization, and intelligence in workpiece loading and unloading on machine tools, along with supporting equipment, delivering robust support for quality improvement, cost reduction, and efficiency enhancement for customers. JiChuangBao integrates advanced manufacturing technologies that combine: basic labor mechanization (CNC) + auxiliary labor mechanization (machine tool automation) + automatic control systems + IoT + big data.

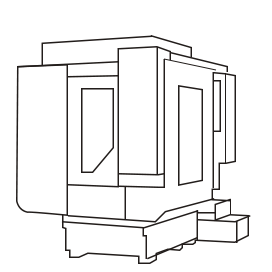

| Item | Description |

|---|---|

| Compatible equipment | CNC lathe, vertical machining, EDM |

| Three-coordinate measuring machine | |

| Maximum load of robot | 15kg |

| Maximum robot working radius | 1300mm |

| Standard end effector | One set |

| Maximum workpiece weight | ≤12kg |

| Loader single-layer space | ≤300(L)*200(W)*150(H)mm |

| Workpiece storage capacity | ≤16pieces (standard) |

| Fixture type | Zero-point quick-change system |

| Repeatability | 0.005mm |