Current Location:Home > News Center > Technical articles > Shutdown and maintenance during the Spring Festival holiday

Current Location:Home > News Center > Technical articles > Shutdown and maintenance during the Spring Festival holiday Remember to stop before the holiday

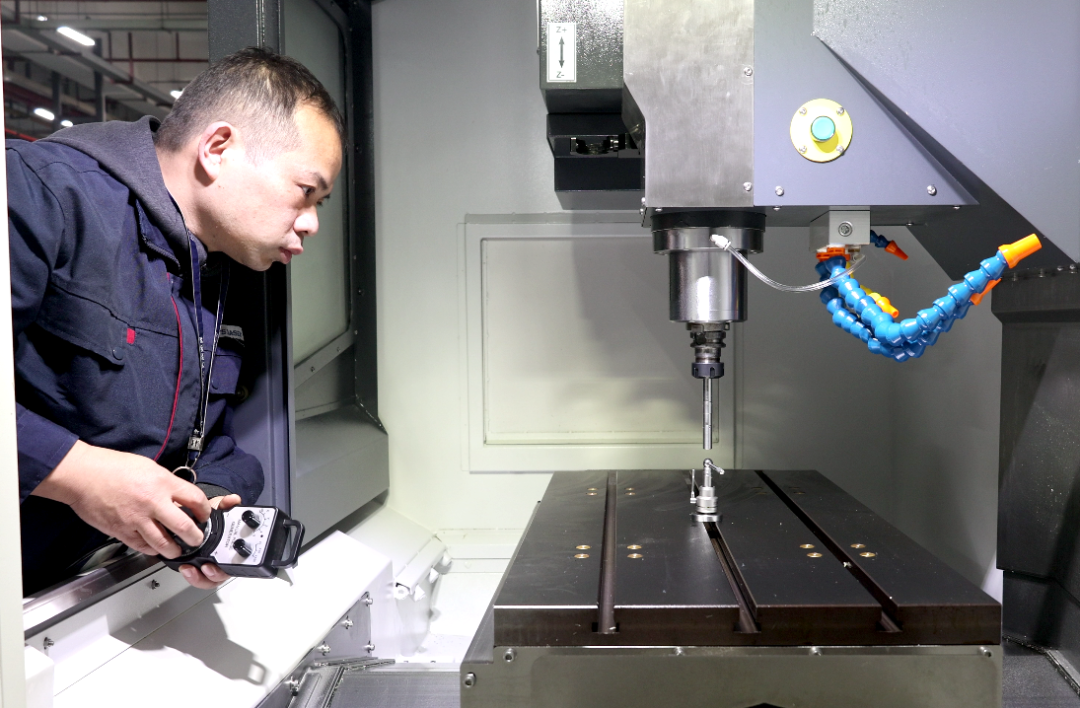

Zero point return: The machine tool moves all axes throughout the entire stroke, filling the surface of the screw and guide rail with lubricating grease. Then, the Z-axis is stopped at the zero point position, the worktable is stopped in the middle, and the tool magazine and robotic arm are stopped at the zero point position.

Spindle cleaning: Do not leave a handle inside the spindle. After removing the handle, clean the spindle cone surface and apply rust proof oil to the handle and spindle cone surface.

Moisture and rust prevention: Apply rust proof oil and lubricating grease to the surfaces of workbenches and fixtures.

Iron chip cleaning: Clean the chips in the machining area inside the machine.

Cutting fluid maintenance: Remove iron filings and impurities from the cutting fluid, and add sterilization and anti-corrosion agents to prevent the cutting fluid from deteriorating and becoming ineffective.

Battery confirmation: Confirm whether all battery voltages of the machine tool are low. When restarting after a long power outage, the machining program, machine parameters, and zero points of each axis may be lost. Please replace the battery regularly. Please implement it one week before the long-term shutdown to confirm that the battery is inserted correctly and in good contact.

Data backup: If you are concerned about the loss of processing programs, machine parameters, and other data, please transfer the required content and save it to a computer or USB drive.

Cut off electricity and gas: Cut off the external power supply of the machine tool, close the gas valve, and turn off the water source.

Attention should be paid when turning on after the holiday

Machine tool cleaning: Clean the rust proof oil and debris from various parts of the machine tool.

Comprehensive inspection: check the peripheral environment of the machine tool; Check for water ingress in the electrical box and any damage to the cables; Check for rust on moving parts; Check whether the cutting fluid has deteriorated, and whether the concentration and liquid level meet the operating requirements. Confirm that the cooling system, lubrication system, electrical system, etc. are functioning properly.

Step by step startup: Check if the machine voltage and air pressure are stable. Under normal circumstances, turn on the device correctly according to the instructions. If there is no alarm during startup, do not perform any action and let the electrical components be powered on for 30 minutes.

Run in preheating: The machine tool runs slowly and automatically for a long time, and rotates the spindle at low speed to allow each moving axis and spindle to fully run in and preheat.

Calibration and testing: The machine tool must be calibrated after being stopped for a period of time, and the machine tool must be calibrated after being warmed up to ensure its accuracy.