Current Location:Home > News Center > Technical articles > Da Zu Machine Tool Operation Manual - Numerical Control Machining is divided into two parts, which are both simple and efficient

Current Location:Home > News Center > Technical articles > Da Zu Machine Tool Operation Manual - Numerical Control Machining is divided into two parts, which are both simple and efficient

———————————————————————————————————————————

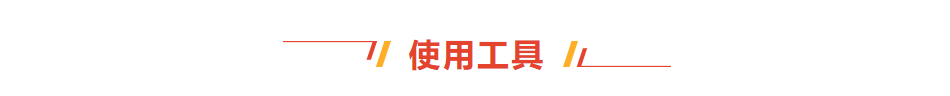

Scoring is to find the zero point of the processed workpiece accurately. If the scoring is not accurate, it can lead to errors or even scrap of the workpiece. Therefore, mastering the scoring technique proficiently is a necessary skill for every CNC operator.

How to achieve fast and accurate centering using commonly used methods that are cumbersome to operate, time-consuming, and even have low accuracy? This article focuses on using tools such as centering rods to perform four sided centering on the Siemens 828D system of the DaZu machine tool, achieving simple and fast operation.

Usage environment: When the required accuracy does not exceed 0.02mm, it is divided into two parts

Main advantages: high universality, fast and efficient

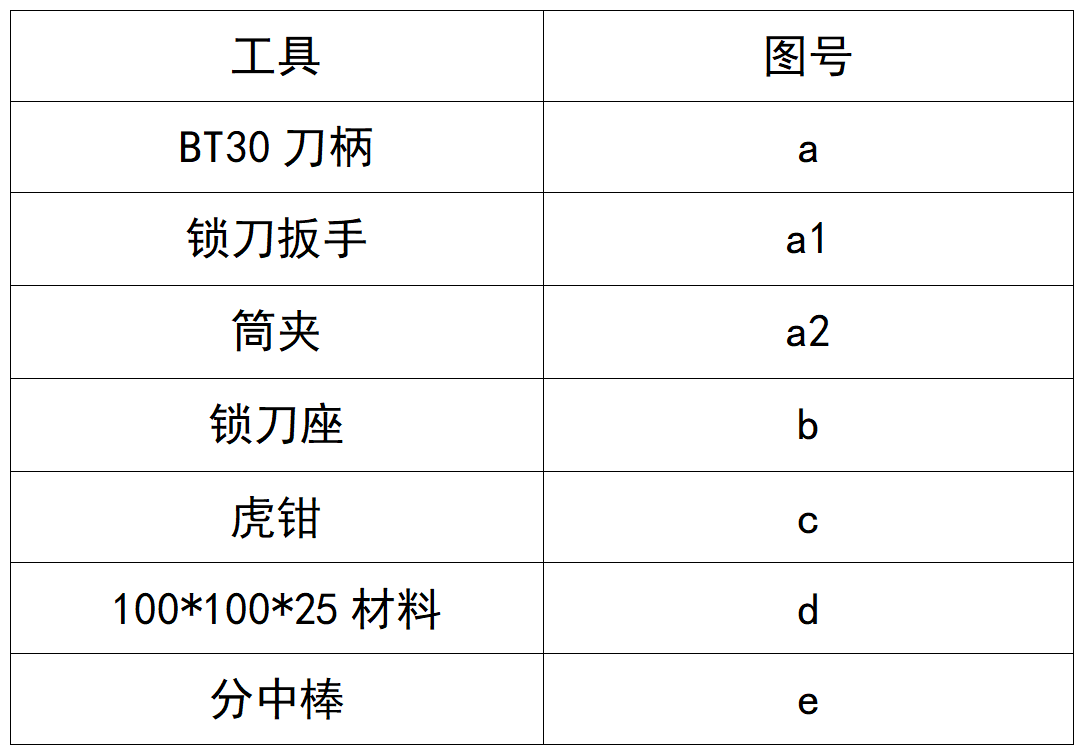

As shown in the figure below, the Siemens control panel is similar to a Windows keyboard application, with functions such as Ctrl+C (copy)/Ctrl+V (paste)/Ctrl+Z (rollback).

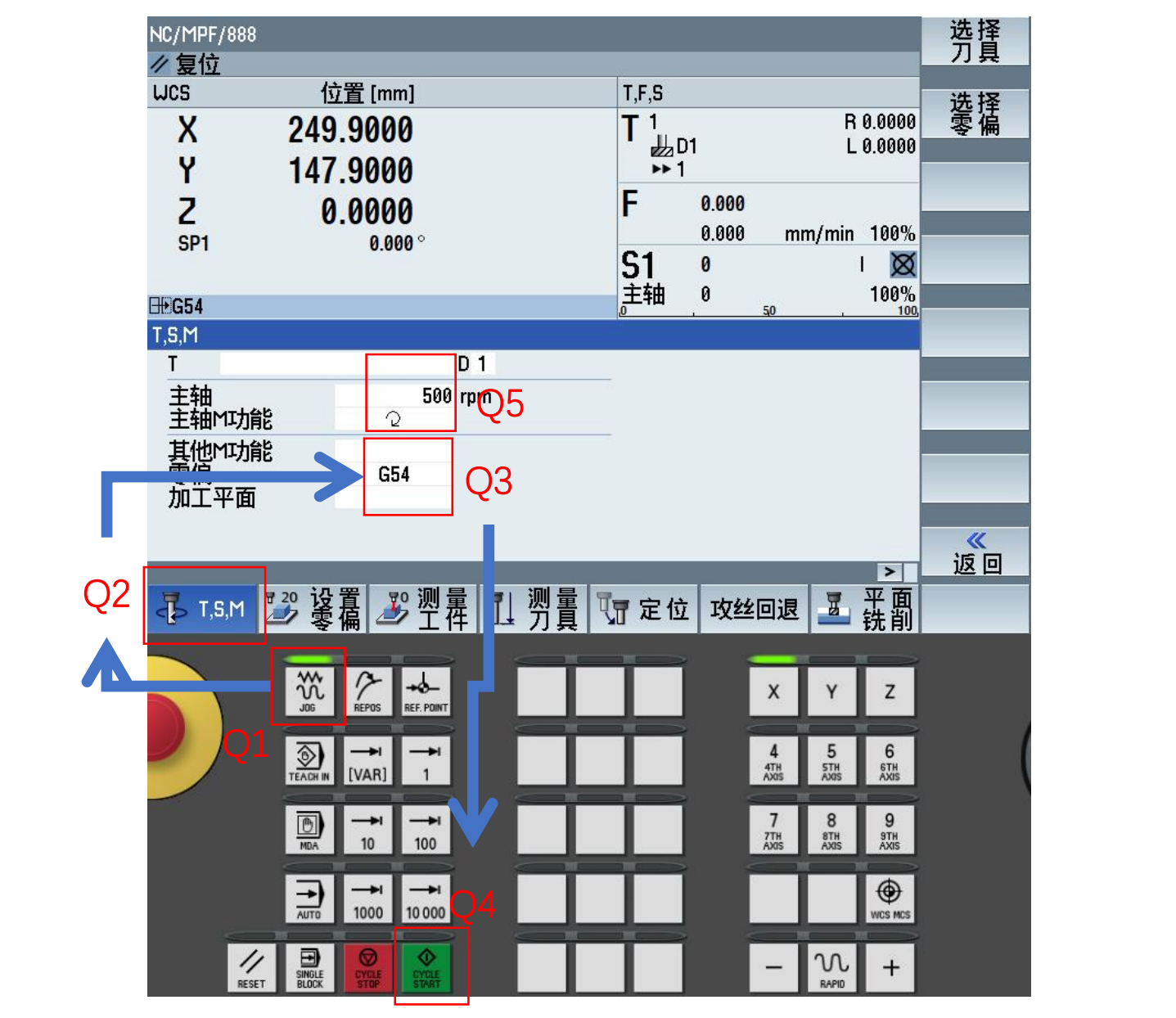

1. Q1: Press JOG fast mode Q2: T, S, M Q3: Zero bias selection (G54) Q4: Press the start button

2. Install the dividing rod onto the main spindle Q2: T, S, M Q5: Main spindle selection (500 RPM) Main spindle M function selection? Q4: Press the start button

Activate coordinate operation diagram ↑↑

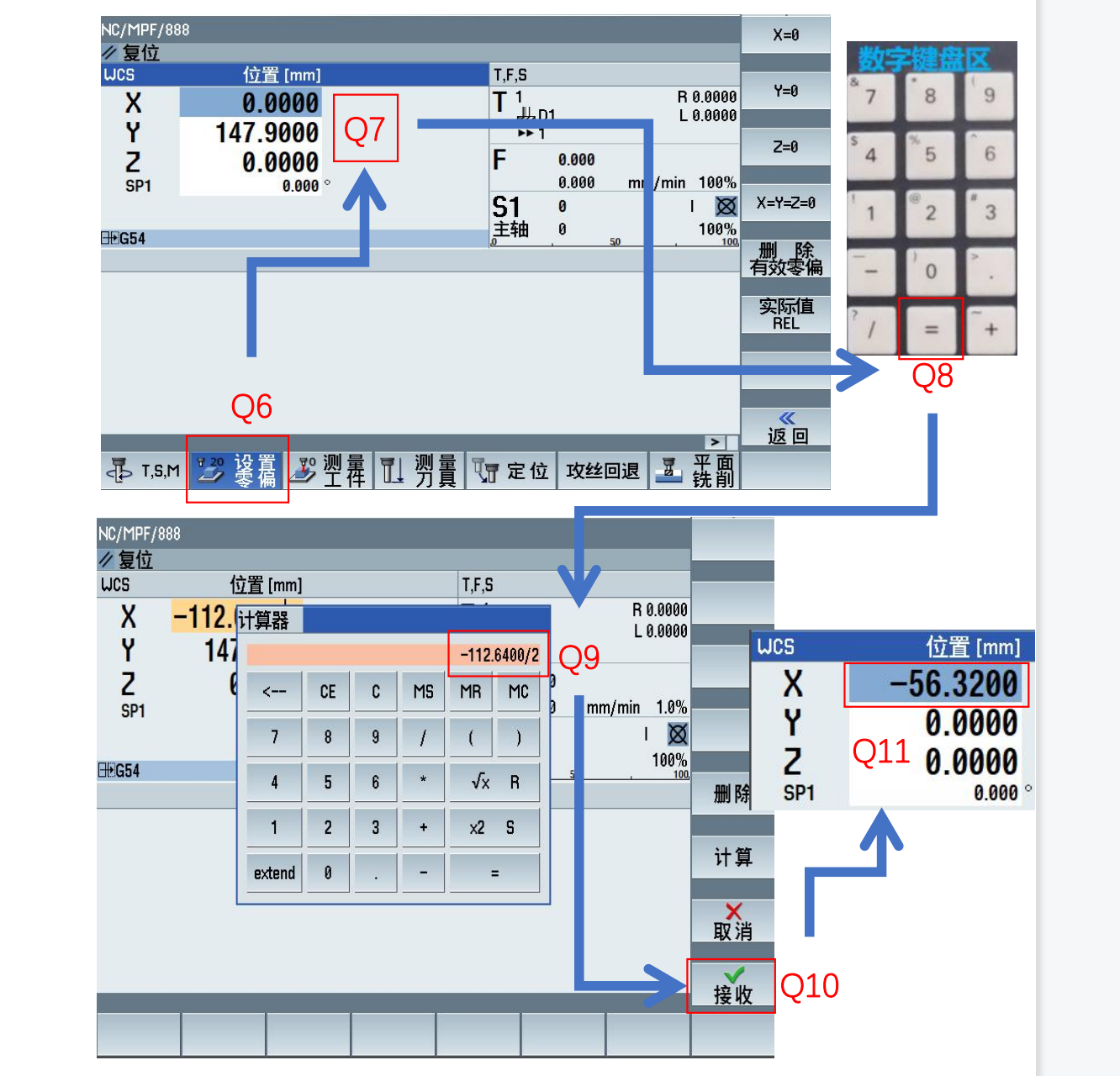

1. Handwheel mode X-axis centering: Move the centering rod to touch the material on the left Q6: Set zero deviation Q7: Reset the X-axis and then move it to touch the material on the right X-axis Q8: Press the=key on the panel

Q9: Computer/2 is half of the current score. Q10: Receive Q11: The current X-axis score has already been entered into the G54 coordinate

Step by Step Diagram 1 ↑↑

2. Handwheel mode Y-axis split: Same principle as X-axis

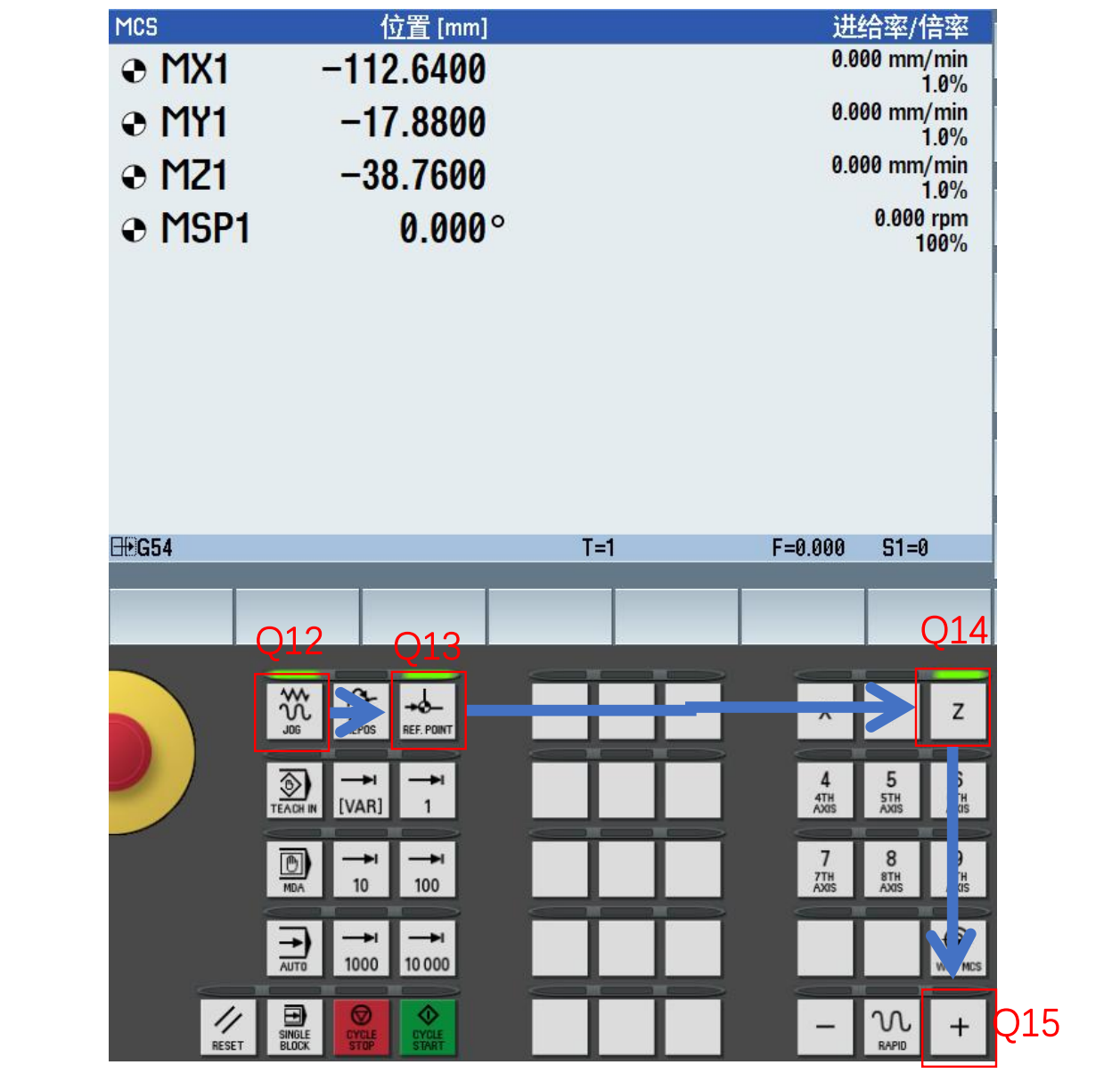

3. Q12: Press JOG fast movement mode Q13: REF.POINT return to zero Q14: Press Z-axis Q15:+Z-axis return to safe position

Step by Step Diagram 2 ↑↑

The accuracy of segmentation directly affects the positional accuracy and processing efficiency of the processed workpiece. Have you learned the simple and practical methods for the daily scoring problems faced by machining personnel in this machine tool classroom?