Current Location:Home > News Center > Technical articles > What is the difference between CNC machine tools and CNC lathes, and how to distinguish them

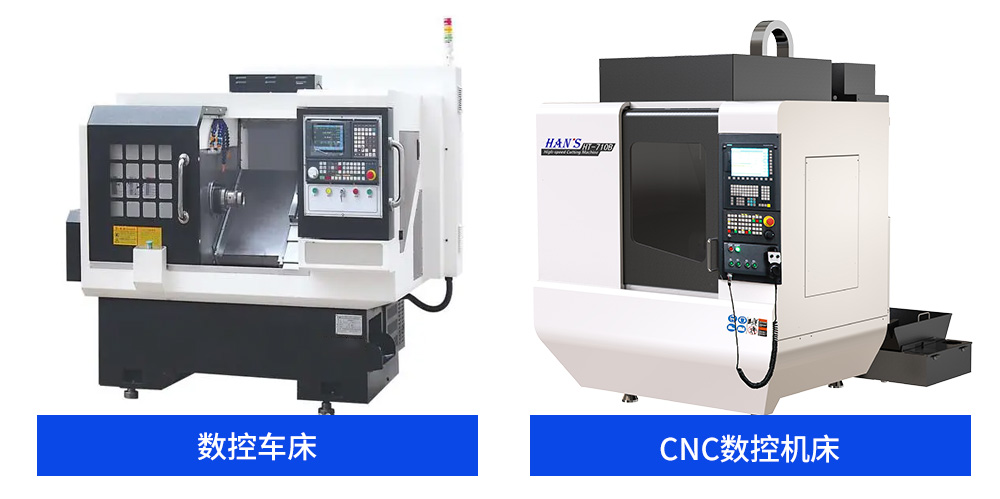

Current Location:Home > News Center > Technical articles > What is the difference between CNC machine tools and CNC lathes, and how to distinguish them CNC machine tooland数控车床They are two different types of machine tools, and their main differences lie in their uses and structures.

CNC machine tool: refers to a machine that uses a numerical control system to process mechanical parts. Numerical control machine tools can perform multi coordinate linkage, suitable for processing various shapes, surfaces, materials, and sizes of parts, and can achieve efficient, accurate, and diversified processing according to different processing requirements. Numerical control machine tools effectively solve complex, precise, small batch, and multi variety part processing problems, making them a flexible and efficient automated machine tool.

Numerical control lathe: refers to a machine that uses a numerical control system to perform turning and machining on shaft parts. Numerical control lathes are commonly used for machining the inner and outer circles, conical surfaces, threads, etc. of shaft parts, and can achieve efficient, accurate, and diversified machining according to different machining requirements.

To distinguish between CNC machine tools and CNC lathes, you can differentiate them based on their main purposes and structural features. If you want to process shaft parts, you can use a CNC lathe; If you want to process other types of parts, you can use CNC machine tools.

If you want to learn more about CNC machine tools and CNC lathes, you can consider the following aspects:

Processing accuracy: Both CNC machine tools and CNC lathes have high processing accuracy, but because CNC lathes are specifically used for processing shaft parts, their accuracy in processing shaft products is usually higher than that of CNC machine tools. However, compared to CNC lathes, CNC machine tools have a higher degree of flexibility, with machining accuracy controlled between 0.05-0.1mm, stable and reliable machining quality, good consistency of products, and stable and reliable yield when machining the same batch of products.

Processing efficiency: The processing efficiency of CNC machine tools and CNC lathes depends on various factors, such as equipment specifications, processing requirements, operating skills, etc. It is more suitable to use CNC lathes for processing inner and outer circles, conical surfaces, threads, and other products. If encountering multi-faceted shapes and non-standard products, using CNC CNC machine tools will be more efficient. Overall, as long as the process is chosen correctly, both CNC machine tools and CNC lathes have high processing efficiency.

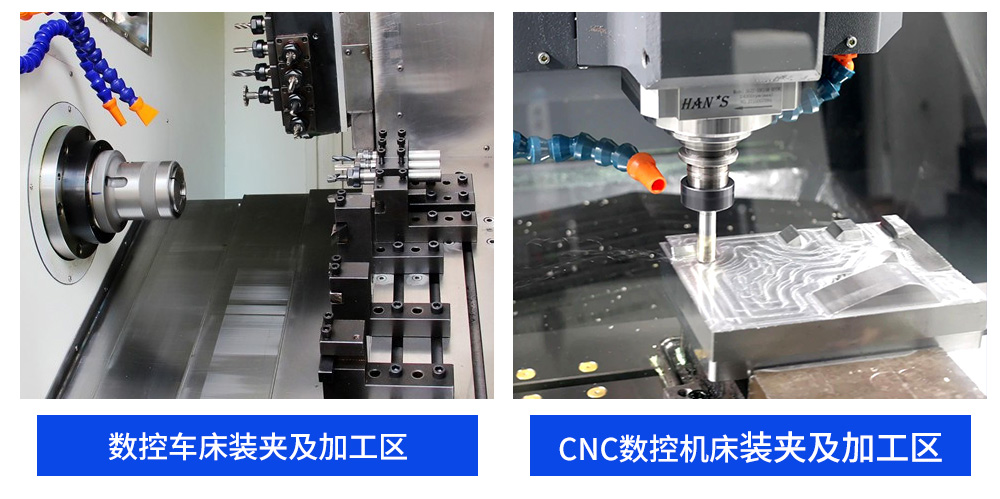

Processing flow: The process of CNC machine tools and CNC lathes is basically the same, including program input, editing, part loading and unloading, tool preparation, observation of processing status, and inspection of parts. The labor intensity is low, and the only difference is in the position of part loading and unloading.