Current Location:Home > News Center > Technical articles > Practical tips for winter maintenance of Dazu machine tools

Current Location:Home > News Center > Technical articles > Practical tips for winter maintenance of Dazu machine tools

The heavy snow arrives, the cold winter begins, and all things hide in winter waiting for spring to come. Da Xue "is the 21st solar term in the lunar calendar, marking the official start of the mid winter season. At this time, the seasonal temperature difference in machining workshops in southern regions is not significant, while in northern regions, the lowest temperature has even dropped to 0 ℃ or below.

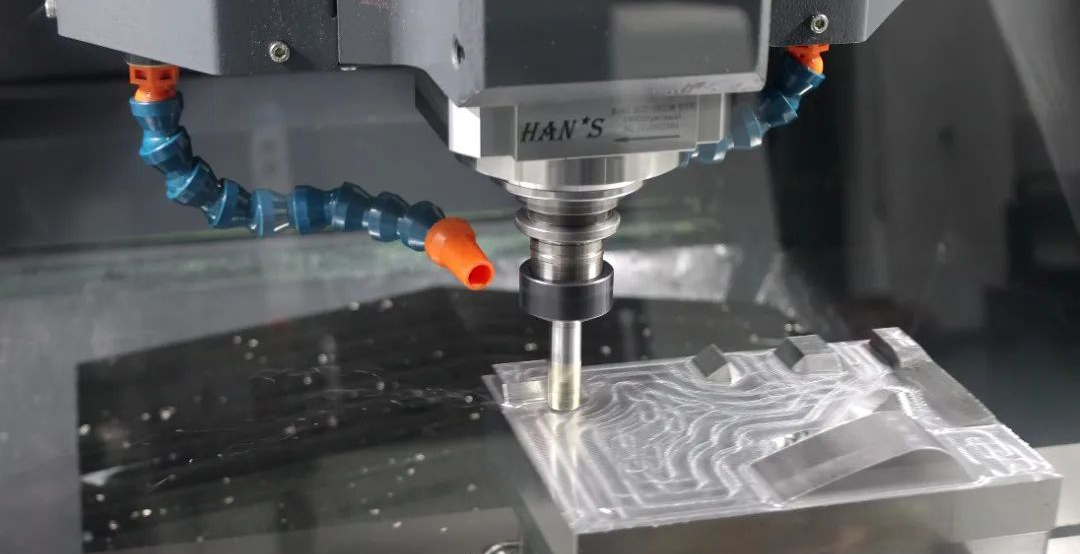

The machining environment temperature of CNC machine tools is too low, which can easily cause changes in positioning and machining accuracy due to uneven temperature rise, and even lead to wear and failure of functional components. Winter is an important period for machine tool maintenance. In order to reduce the impact of environmental temperature on machine tools and minimize unnecessary losses, DaZu Machine Tool offers 6 practical tips for winter maintenance to help you ensure stable and efficient production even in severe cold and deep winter~

01

temperature control

The more precise the machine, the stricter the requirements for the operating environment temperature. The low temperature in winter can easily affect the normal operation of mechanical equipment. Please ensure that the working temperature is within the appropriate range of 5 ℃~45 ℃ to avoid reducing machine performance and affecting machining accuracy due to low temperature.

02

Power on preheating

In winter, the ambient temperature is low, and materials may undergo some physical changes, which can affect the machining accuracy of machine tools. By starting the equipment in advance and running it for a period of time, various components of the equipment can be preheated to a constant temperature, achieving good working performance and condition. It is recommended to preheat for at least 10-20 minutes before proceeding with processing operations.

03

cooling unit

If it cannot be guaranteed that the cutting fluid will not freeze at room temperature, the best way is to clean the cutting fluid before leaving work, and at the same time, remove the cutting fluid from the spindle and machine to prevent freezing and blockage or rupture.

04

lubrication system

Choose lubricating oil suitable for low-temperature environments and regularly replace and maintain it to ensure the normal operation of the lubrication system. Use the lubricating oil specified in the instruction manual and replace it promptly.

05

Electrical equipment

Check the wiring and connectors of electrical equipment for looseness, damage or leakage, regularly clean and maintain electrical equipment to ensure its good operating condition.

06

Cleaning operation

Timely clean the iron filings and oil stains such as the spindle and protective cover, and clean the dust and debris on the surface and inside of the equipment. Perform standardized daily cleaning and maintenance of machine tools according to operating procedures and instructions.

To do a good job, one must first sharpen their tools. Nowadays, the precision requirements and automation level of CNC machine tools are becoming increasingly high, and the requirements for environmental temperature and humidity, cutting fluid, lubricating oil, etc. are also becoming more and more strict. Proper and standardized operation combined with careful maintenance can reduce failures and consumption, extend the service life of machine tools, and maximize output efficiency and benefits.

Unified Service Hotline for Dazu: 400-666-4000

If you have any questions, please contact us at 0755-2319919

If you have any questions related to machine tools, please feel free to call us. For all users who use Dazu machine tools (including those who purchase second-hand phones), Dazu machine tools can provide free on-site inspection, maintenance, and other after-sales services. We are dedicated to providing you with service and support!