Current Location:Home > News Center > Company News > How about Dazu Machine Tool? Listen to what the customer has to say!

Current Location:Home > News Center > Company News > How about Dazu Machine Tool? Listen to what the customer has to say! Numerical control machine tools are industrial mother machines for high-end equipment manufacturing, serving as the cornerstone for achieving automation and intelligence, and promoting the rapid development and transformation of modern industry.

Customer review: "DaZu machine tool equipment has an advantage over its peers in processing high-precision parts. Moreover, machining that originally required several processes can be completed in one step (rough machining+precision machining) if the equipment stroke and accuracy are sufficient, saving time and effort, and greatly improving production efficiency. It is reported that DaZu machine tool equipment accounts for about 60% -70% of the main machining equipment in Yuantaida

DaZu machine tool equipment can meet the current (company) processing needs, and DaZu machine tools will be given priority consideration for future machining needs

With the continuous development of manufacturing and technological progress, terminal products have increasingly high requirements for precision, quality, processing efficiency, and other key components. As the "heart" and "source" of industrial manufacturing, machine tools are constantly developing and transforming, presenting trends such as intelligence, digitization, flexibility, high speed, and high precision, flexibly meeting various processing methods and production needs.

In this column, we visited Shenzhen Yuantaida Precision Machinery Co., Ltd. to gain a deeper understanding of how Dazu Machine Tool's mature processing solutions can increase efficiency and speed for users during their enterprise transformation and development process.

Shenzhen Yuantaida Precision Machinery Co., Ltd. is an independent research and development production enterprise specializing in the manufacturing and design of high-precision automation equipment components and automation transmission modules. It is an excellent supplier to multiple listed companies. With the diligent pursuit of high-quality products and first-class services, the company has won the trust of high-quality customers and a good reputation in the industry.

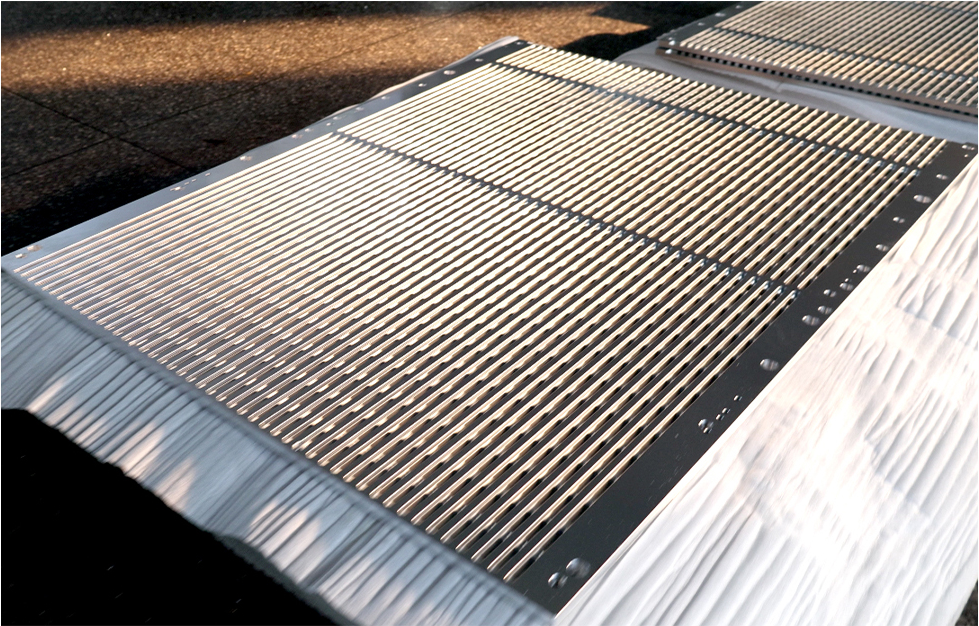

I first came into contact with DaZu Machine Tool in 2013 and used the HT710, which has excellent accuracy, stroke, and other features. ”Mr. Ni, the head of the Engineering Department at Yuantaida, stated that "HT710 has significant advantages in cutting force and machining accuracy compared to other domestic brands. ”Previously, Yuantaida had established good partnerships with other departments of Dazu Group. Based on a deep understanding of Dazu Group's extremely high requirements for equipment quality and performance, they attempted to use Dazu machine tools and equipment, and the actual processing and use results did not disappoint expectations.

Mr. Ni stated that DaZu machine tool processing equipment has fast speed, good flatness, stable performance, and low failure rate, especially in high-precision component processing, it has advantages over its peers. Moreover, processing that originally required several steps can be completed in one step with sufficient equipment stroke and precision, achieving a "double improvement" in efficiency and effectiveness.

Entering the production workshop of Yuantaida, workers and equipment are operating in a lively and orderly manner. Rows of large-scale machine tool processing equipment are neatly arranged and operate stably and efficiently, with a large quantity. It is reported that the number of DaZu machine tool equipment accounts for about 60-70% of Yuantaida's main processing equipment. These high-performance CNC machine tools have pressed the "fast forward button" for Yuantaida to compete in the market.

Around 18-19, we purchased an additional 30 HV1165 machine tools from Dazu at once. In addition, to meet the research and development needs, one HL2015 was purchased, mainly for flexible processing of OLED panels. The large workpiece is 1.6m * 1m, with a surface flatness of up to 3 threads (0.03mm), high precision, and can effectively meet customer quality requirements. ”Mr. Ni introduced that "previously, using other brands to process cutting tools was small, and the problem of parameter matching increased the cost. HV1165 can include more products and strokes, and the accuracy can also be achieved, so it was added for purchase. The original (precision) data did not meet the requirements, but after switching to the larger family (HV1165), it can reach 0.003mm and the processing range is also relatively wide

Not only has DaZu Machine Tool received high praise from user companies for its high-quality intelligent manufacturing solutions, but also for its comprehensive and thoughtful after-sales service. DaZu Machine Tool has a fast after-sales response speed. We can promptly answer any questions we don't understand and provide effective technical support and solutions quickly

Mr. Ni's message, "DaZu Machine Tool Equipment can meet the current (company's) processing needs. If there are machining needs in the future, DaZu Machine Tool will be given priority consideration. We hope that DaZu Machine Tool will continue to strengthen technological innovation, grow bigger and stronger, and we also hope that both sides will have more cooperation, collaborative innovation, and joint development in the future

Thank you for the support and trust of the user enterprise. DaZu Machine Tool will continue to uphold its original intention, forge perseverance, continuously strengthen technological innovation and process upgrading, and create high-performance and high-efficiency CNC automation intelligent manufacturing solutions. We are willing to grow and cooperate with new and old users and partners for mutual benefit!

|Yuan Taida recommends hardcore equipment

DaZu Machine Tool Vertical Machining Center - HV1165

Widely used in key automotive components, high-precision medical equipment, precision machinery manufacturing, precision hardware and other industries. X/Y/Z axis travel 1100/650/600mm

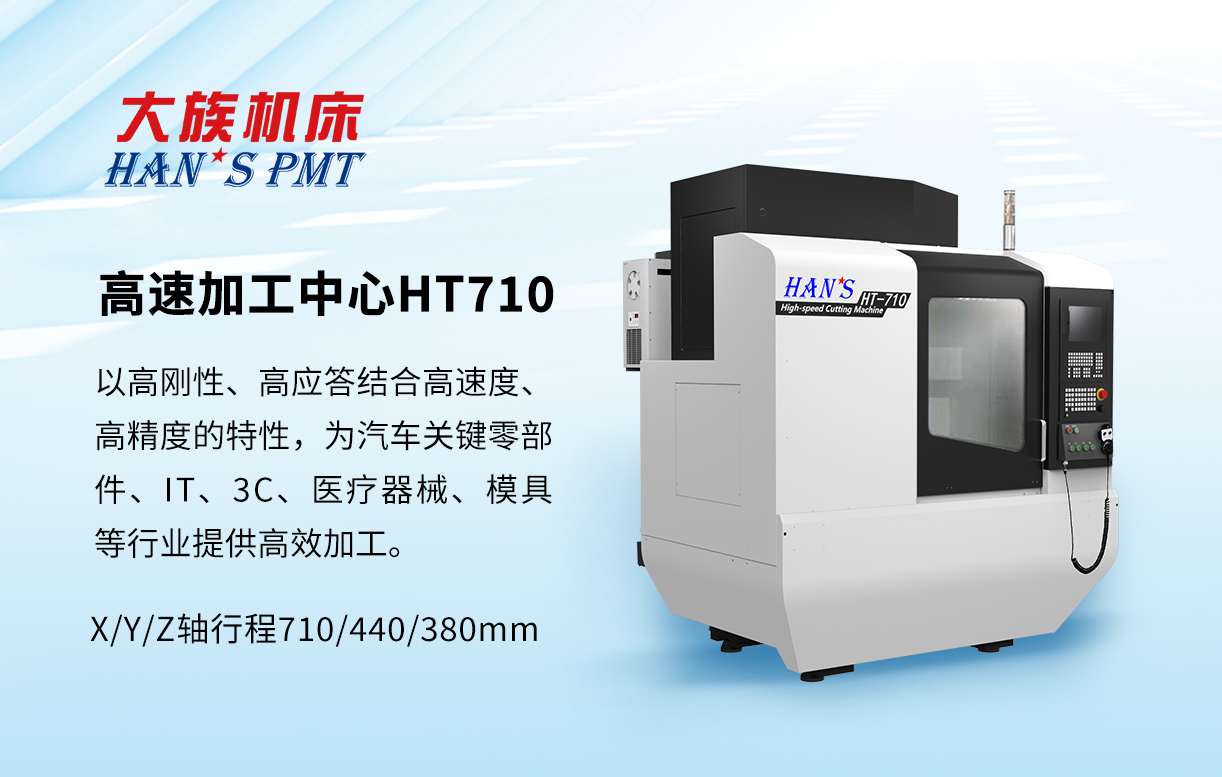

Dazu Machine Tool Vertical Machining Center - HT710

With the characteristics of high rigidity, high response, high speed, and high precision, it serves as a key component for automobiles IT、3C、 The medical device, mold and other industries provide efficient processing.X/Y/Z axis travel 710/440/380mm

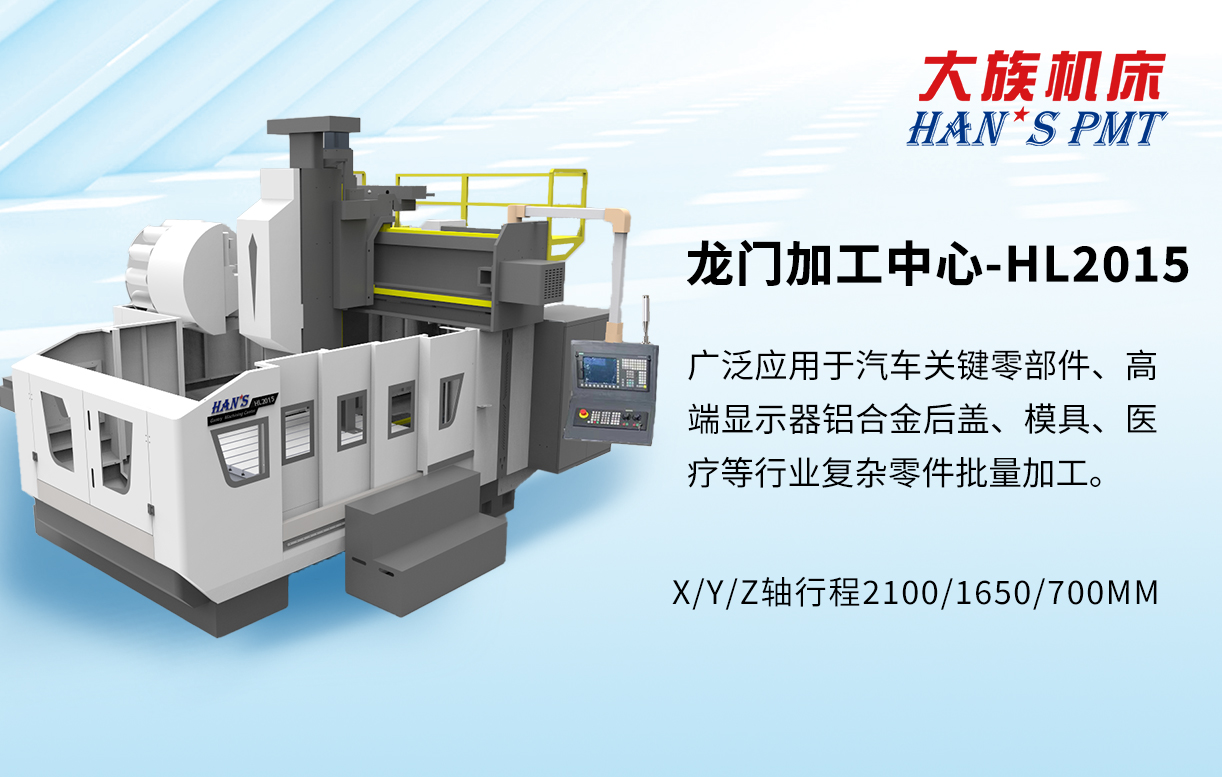

Dazu Machine Tool Longmen Machining Center - HL2015

Widely used for batch processing of complex parts in industries such as automotive key components, high-end display aluminum alloy back covers, molds, and medical equipment.X/Y/Z axis stroke 2100/1650/700mm