Current Location:Home > News Center > Company News > The best tool for mass production and processing in the 3C industry - the latest CNC equipment HV500 developed by Dazu Machine Tool

Current Location:Home > News Center > Company News > The best tool for mass production and processing in the 3C industry - the latest CNC equipment HV500 developed by Dazu Machine Tool With the continuous development of the national economy, China's manufacturing industry is also constantly growing, especially in the 3C industry and new energy vehicle industry. They have become a part of human life, holding mobile phones and driving new energy vehicles on the road. Of course, all of this is inseparable from high-efficiency and high-performance machine tools.

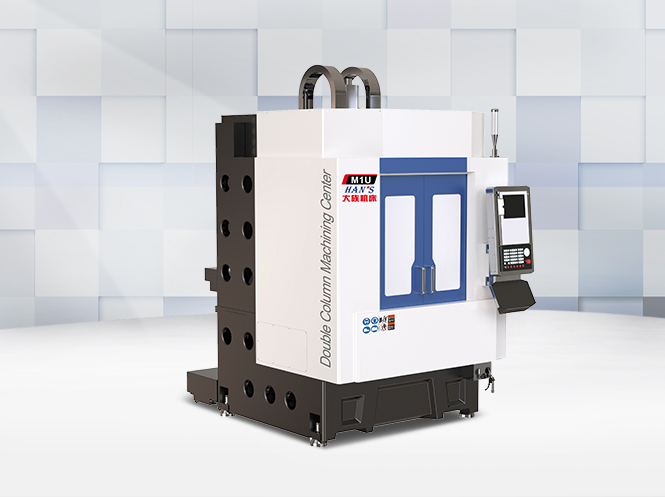

The Dazu Machine Tool HV500 is a high-efficiency, high reliability, and high-performance portal small high-speed machining center widely used in the 3C industry, new energy vehicle industry, and other fields for processing. It has high-speed, high-precision, and high-quality machining control functions, optimizes the acceleration and deceleration characteristics of each axis, and significantly shortens the production cycle. And during high-speed machining, it can suppress mechanical vibration.

1. Processing performance

High stability: The unique left-right symmetrical frame structure and front and rear symmetrical H-shaped column structure effectively ensure the stability of the machine equipment with a low center of gravity structure. In addition, the use of high-precision and high stability mineral casting materials makes the equipment more stable, ensuring no vibration during processing.

High rigidity: The distance between the spindle center and the guide rail is 190mm, while the distance between the spindle center and the guide rail of ordinary machine tools is 490mm. This design further improves the high rigidity of the machine.

High precision: The carefully designed Mihanna casting structure enables the machine tool to maintain precise geometric accuracy, motion accuracy, and positioning accuracy for a long time; Secondly, a symmetrical and thermally balanced design method is adopted to improve the thermal deformation of the machine tool structure, resulting in higher machining accuracy of the machine tool.

2. High operating rate

The high reliability H-type gantry structure ensures the long-term service life and stability of the machine.

Excellent preventive maintenance function, effectively avoiding mechanical failures.

Unique maintenance function, modularity can be replaced at any time, reducing downtime.

3. Usability

✦ Convenient operability, easy to achieve flexibility in the application of advanced functions.

High scalability, achieving unified control over peripheral devices.

Application of automation functions to achieve efficient coordination with machines.

4. Key parameters of the portal small high-speed machining center HV500