Current Location:Home > News Center > Company News > Universal Five Axis Machining Center - Dazu Machine Tool M2U

Current Location:Home > News Center > Company News > Universal Five Axis Machining Center - Dazu Machine Tool M2U Multi axis, linkage, high rigidity, high precision, high surface quality, advanced control system, user-friendly interactive interface, low failure rate of continuous operation, the versatile five axis machining center M2U of Dazu Machine Tool meets all machining needs!

1. High rigidity machine tool structure

Stable base design, integrated structure of crossbeam and column, reasonable BC axis turntable design, reducing the error superposition of each axis and improving the dynamic characteristics of each axis;

Combining modern finite element analysis software to continuously optimize and improve the rigidity of the main structure of the machine tool, achieving optimal design;

The bed body is made of high-quality gray cast iron material and cast using the Mihanna casting process. It undergoes secondary aging treatment to eliminate internal stress, ensuring high rigidity, seismic resistance, and stability of the main structure of the machine tool.

2. High precision and high stability machining capability

The X/Y/Z axis of M2U is equipped with precision ball bearing linear tracks for load-bearing (strong seismic resistance, lightweight design, higher response);

The motor and high-precision ball screw are directly connected for driving, and the C-grade ball screw is pre stretched and installed to further improve transmission rigidity and positioning accuracy;

The bed body adopts the Mihana casting process and undergoes complete aging heat treatment to eliminate stress, resulting in high rigidity and stable precision of the machine tool;

3. High efficiency and high-quality surface processing

The fast moving speed of X/Y/Z axis is 20m/min, and the fast moving speed of BC axis is 20/40 m/min.

German imported Rexroth MTX-CML efficient intelligent five axis CNC system, combined with high-quality BBT30 tool holders, easily meets the requirements of high-quality surface processing.

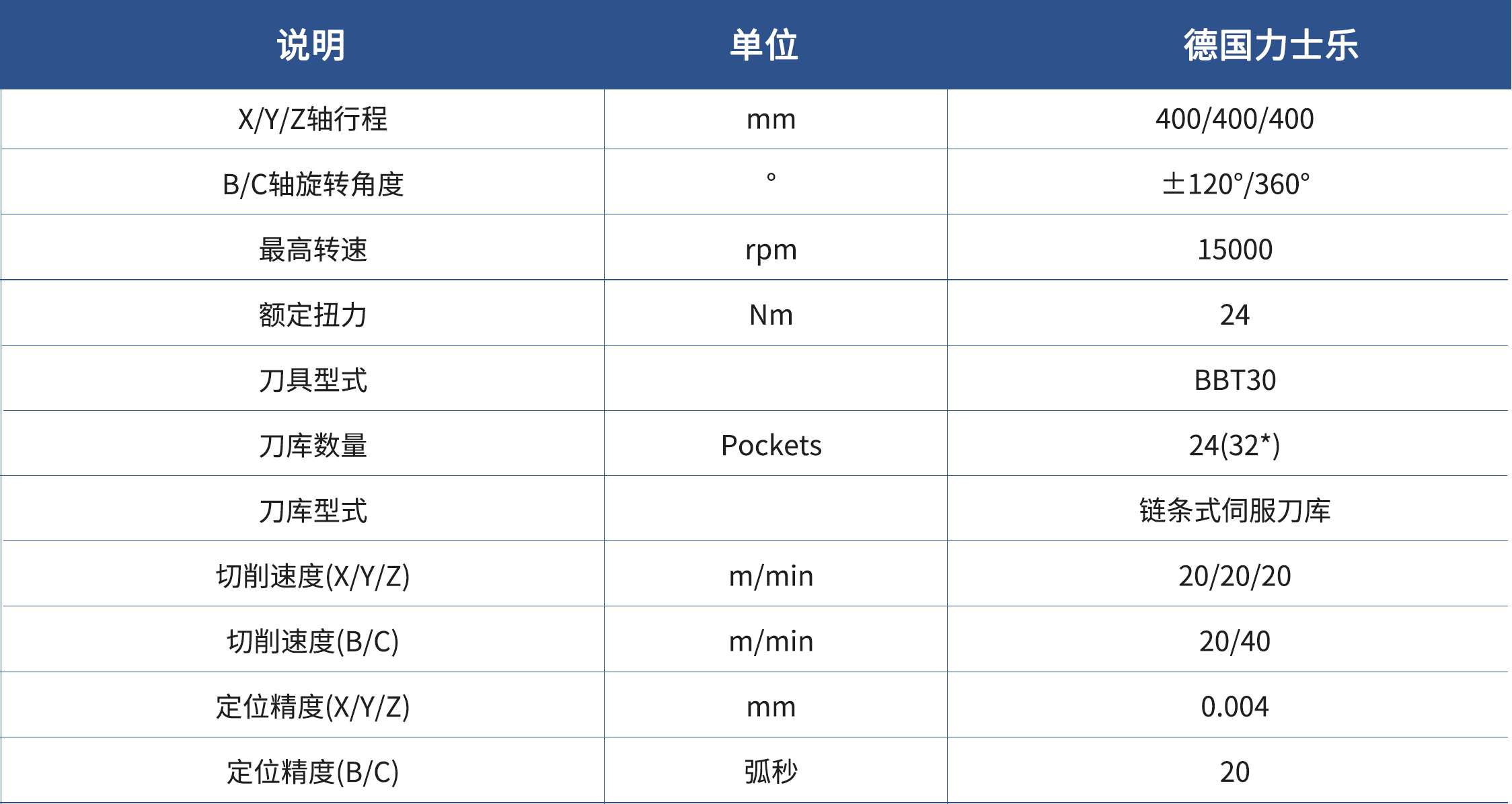

4. Five axis machining center - Key parameters of DaZu machine tool M2U