Current Location:Home > News Center > Company News > DaZu Machine Tool HV855: Empowering the Industry with Digital Intelligence, Efficient and Multi functional with One Machine

Current Location:Home > News Center > Company News > DaZu Machine Tool HV855: Empowering the Industry with Digital Intelligence, Efficient and Multi functional with One Machine

High rigidity structure, high processing performance, and high operating speed rate

Simplify complexity and gather intelligence for multiple effects

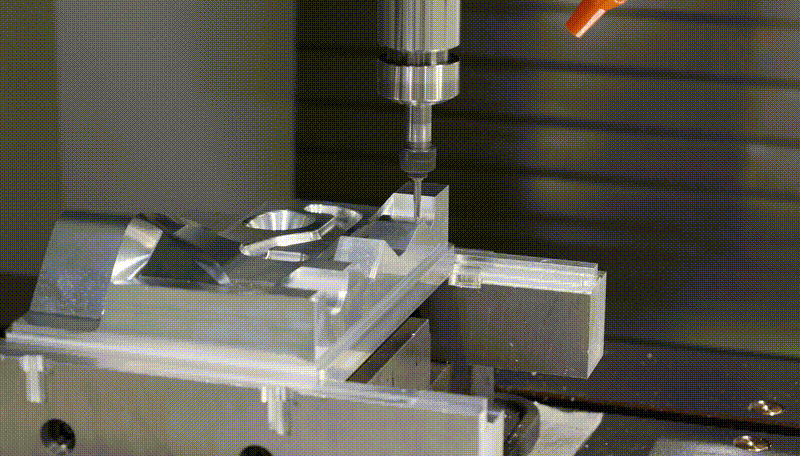

Fine processing, excellent application

Efficient and flexible processing tool for complex parts

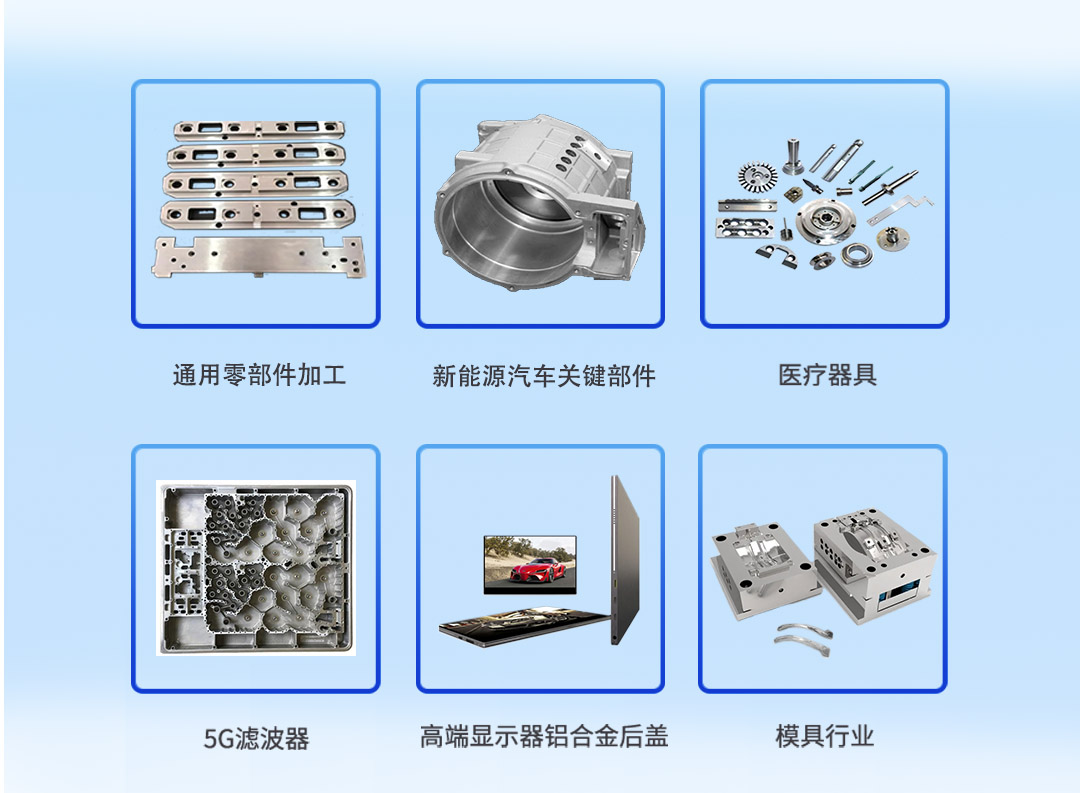

Processing Application Scenario - Vertical Machining Center HV855

Widely used in industries such as general processing, key components of new energy vehicles, medical, 5G, display back covers, molds, etc.

——————High rigidity structure, as stable as a rock——————

The entire body adopts high-quality Mihanna casting technology

And undergo complete aging heat treatment

stress relieving

Ensure high rigidity and stability of the machine tool

Through finite element analysis

And multiple optimization certifications

A machine tool structure with high rigidity and superior vibration resistance

Cooperate with the body to stabilize the base

Ensure stable cutting of the machine at high speeds

Enable machine tools to maintain precision for a long time

Geometric accuracy, motion accuracy, and positioning accuracy

Large span guide rail

Large span slider support

Further enhance the structural rigidity of moving parts

High precision machining, integrating intelligence and multiple effects——————

The positioning accuracy is accurate to 8 μ m

The precision of repeated positioning is accurate to 5 μ m

Servo motor directly connected to high-precision ball screw

No reverse clearance, further improving positioning accuracy

High precision screw, pre stretched installation

Eliminating accuracy changes caused by partial thermal elongation

More stable accuracy and stronger rigidity

Nano level computational numerical control system

high dynamic response

Excellent surface fine treatment technology

Adaptive processing technology

Support digital upgrade

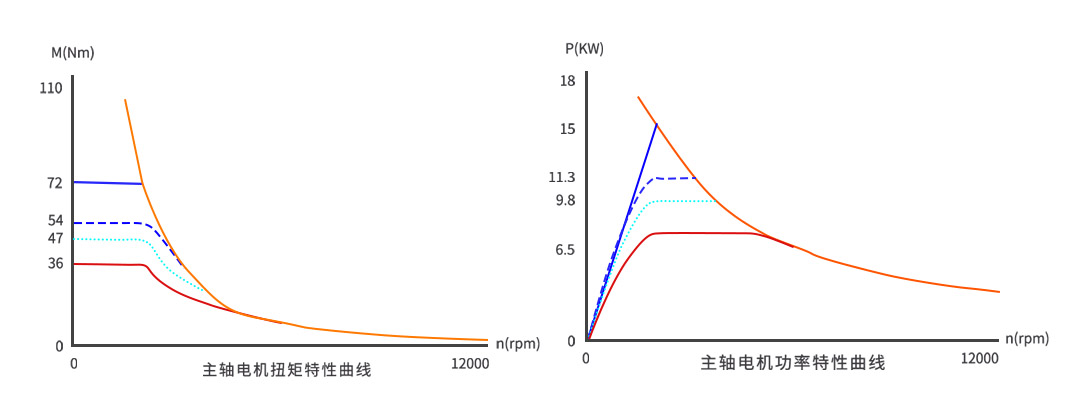

——————High production efficiency, increased energy and improved quality——————

High speed direct drive feed

Three axis fast movement 48m/min

Z-axis maximum acceleration 1.1g

The spindle speed can reach up to 12000rpm

The spindle motor is directly connected to the spindle

Increase start stop speed

Improve processing efficiency

Patent type high-speed tool changing servo system

Synchronous travel control positioning

Further shorten processing time

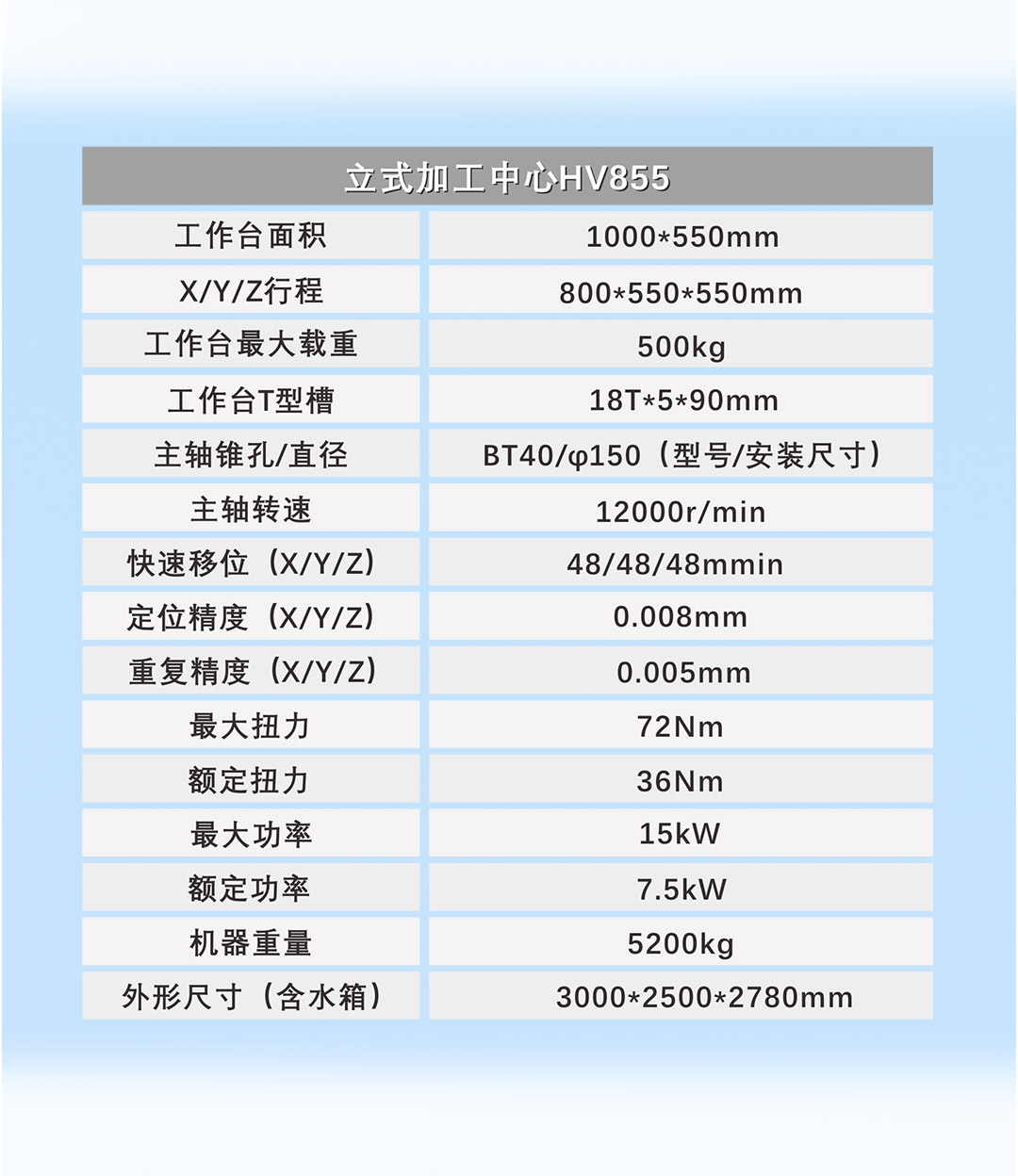

——————Technical parameters——————

Vertical machining center HV855

It is a high-precision, high-speed, and high-performance product

A machine tool specifically designed for batch processing of complex parts

Can significantly save users time and costs

Improve efficiency and effectiveness

Realize greater commercial value