Current Location:Home > News Center > Company News > CNC machining center manufacturer DaZu Machine Tool takes you to understand the production process of machine tools

Current Location:Home > News Center > Company News > CNC machining center manufacturer DaZu Machine Tool takes you to understand the production process of machine tools Machine tools are known as "industrial mother machines" and are the foundation and cornerstone of industrialization. And high-end machine tools are the core of high-end equipment and intelligent manufacturing. Whether using processes such as milling, drilling, boring, expanding, reaming, countersunking, tapping, etc., to produce high-quality products, high-precision, high-efficiency, and high stability machine tool processing is required. As the "tool of manufacturing", the standard of machine tool production and assembly process directly affects the accuracy, quality, and reliability of machine tool machining parts.

Dazu Machine Tool is committed to developing applications in the mid to high end precision machine tool market, with multiple series of models including standard, gantry, profile, precision carving, and five axis intelligent, widely used in industries such as new energy vehicles, 3C, medical, machinery, and precision mold processing. The production and manufacturing capabilities of Dazu Machine Tool are at the leading level in the industry, and now there are tens of thousands of devices operating stably on user sites.

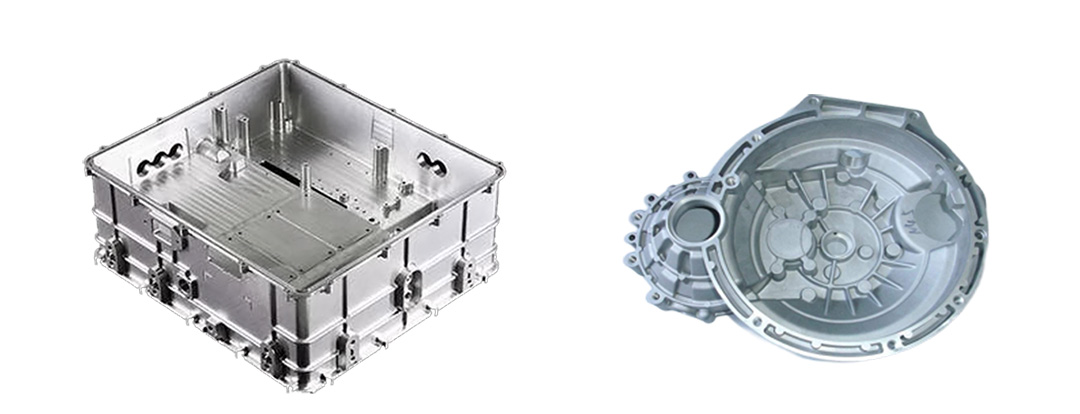

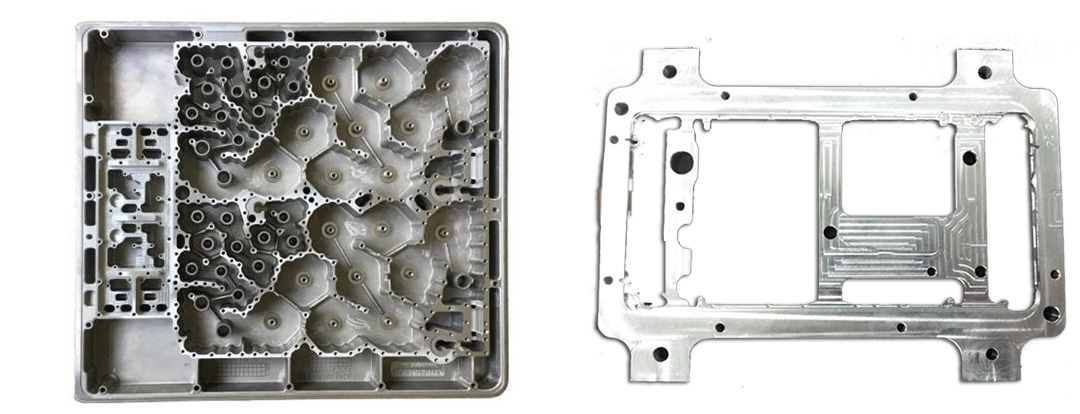

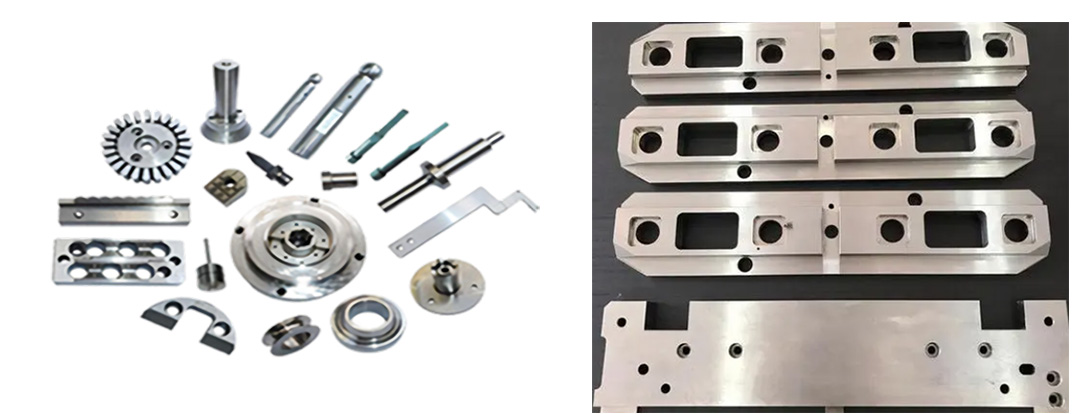

△ Application examples

In manufacturing and assembly, DaZu Machine Tool has always adhered to strict high requirements, implemented a quality management system that exceeds industry standards, valued independent research and development and technological innovation, and equipped with customized CNC systems with high reliability and high matching, as well as world-class testing equipment and auxiliary tools, to ensure product reliability and assembly consistency.

New Energy Industry - Battery Control Box

New energy industry - motor casing

3C Industry -5G Filter

3C Industry - Mobile Phone Structure

Medical Industry - Medical Devices

Automation Industry - Non standard Parts

Exquisite skills

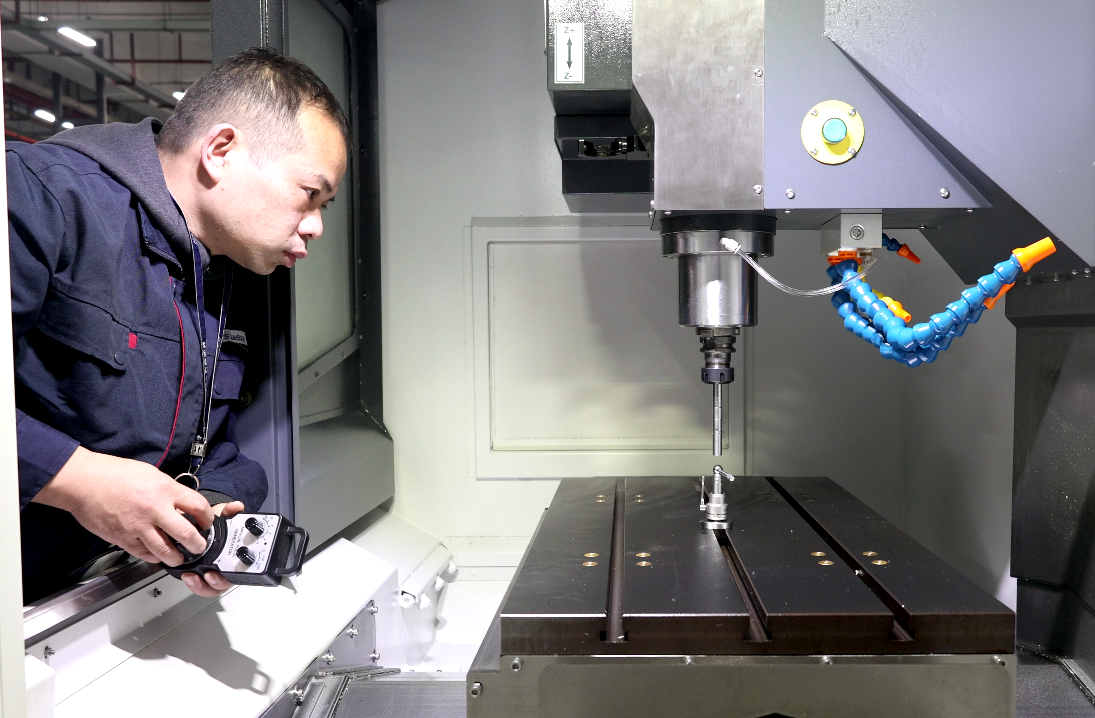

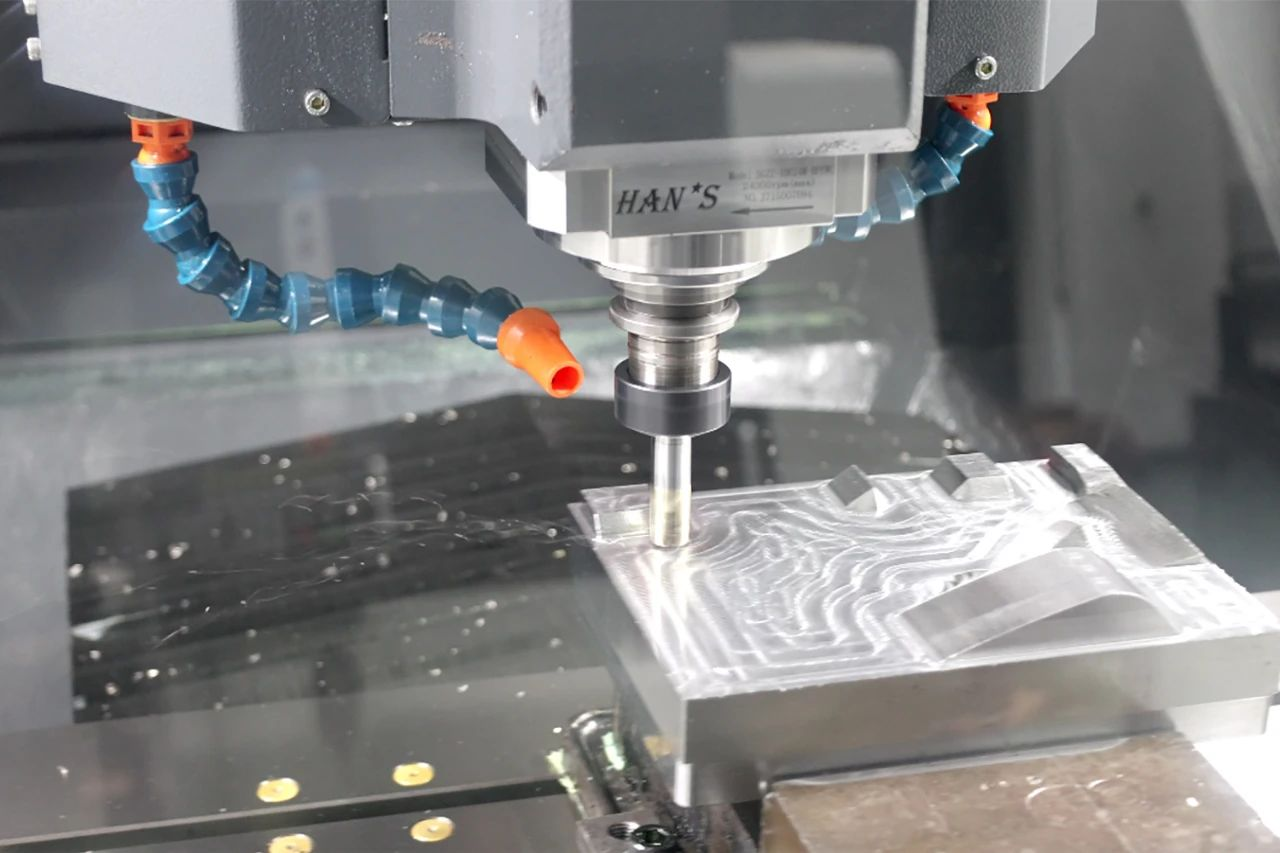

Manufacturing assembly and cutting process

Entering the production workshop of Dazu Machine Tool, the quality consciousness and craftsmanship spirit of "winning with excellence and striving for excellence" can be seen everywhere. On the production line, from assembly, installation of spindle motors, quality and accuracy inspection, adjustment of tool magazine, to debugging of castings, sheet metal parts, functional components, etc., to different types of screws and standard torque values corresponding to different workstations. Every part and every process requires repeated scraping and verification.

Compared to other automation equipment, machine tool manufacturing and assembly involve a large amount of manual labor and cannot be replaced by machines. For example, in the carving process, only manual carving can achieve smoother component joint surfaces, correct and optimize errors and defects left by mechanical processing. As a key core process of machine tools, shoveling technology determines the geometric accuracy and precision of CNC machine tools, as well as the stability and durability of machine tools for long-term use.

DaZu Machine Tool has an experienced and skilled professional team with mature and rich project experience and technical accumulation in machine tool production and manufacturing. At the same time, it regularly conducts production assembly and shoveling technology training and skill competition assessments, so it has an irreplaceable leading advantage in machine tool accuracy and stability.

Strive for excellence

High quality control of products and processes

Quality is the life of an enterprise. In the process of machine tool manufacturing, assembly, precision, and quality inspection, DaZu Machine Tool adheres to the product design concept of high standards and high added value. With a sound quality control system and standards, every detail is strictly done.

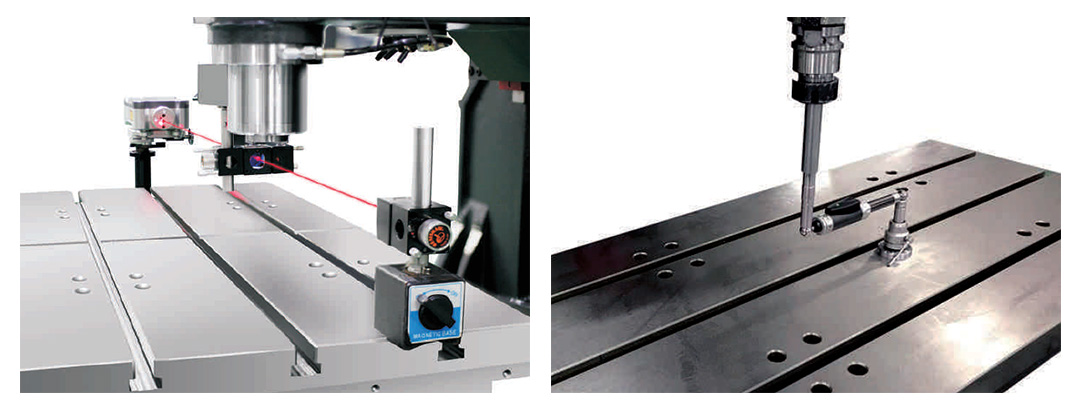

△ Accuracy detection

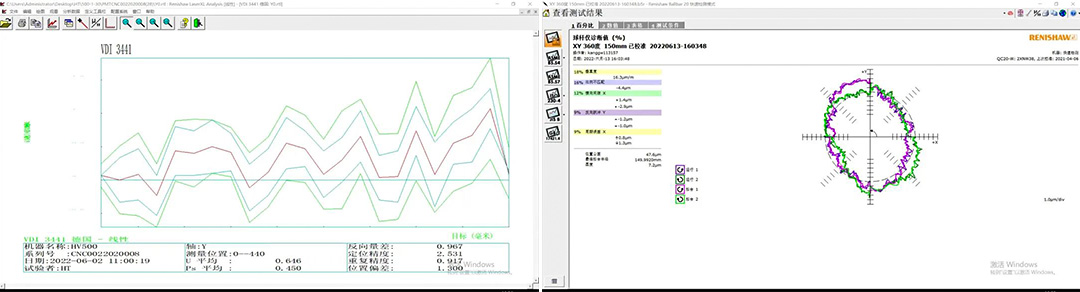

Laser inspection is carried out using VDI/DGQ 3441 as the inspection standard, and detection equipment and auxiliary tools such as laser interferometers and Renishaw ball bar instruments from the UK are used to ensure the accuracy of machine tool positioning, repeatability, perpendicularity, parallelism, and roundness.

interferometer

Renishaw golf club instrument from the UK

Laser interferometer detection interface

Renishaw golf club testing interface in the UK

The machine tool adopts a straight type 20000rpm/24000rpm high-speed spindle and a high repeatability positioning accuracy design, achieving 100% spindle performance. The positioning accuracy of the XYZ axis is required to be controlled within 0.005/300mm, the repeated positioning accuracy of the XYZ axis is required to be controlled within 0.003mm, and the circular accuracy of the XY, YZ, and XZ axes is required to be controlled within 0.01mm.

In terms of process optimization, the screw installation adopts a "fixed+fixed" method, which can withstand bending loads 200% higher than "fixed+support"; The knife arm model adopts a large capacity knife magazine design and a patented pneumatic quick tool changing device; Lightweight and modular design of mobile parts enables flexible and efficient processing.

High adaptability

Customized system secondary development

Adopting an efficient intelligent CNC system, multiple system options can be provided for different needs. The system supports secondary development, adaptive processing technology, and flexible matching of customized user needs. The system adopts unique motion control technology, which greatly improves the surface processing quality of the workpiece and shortens the processing time.

Industrial mother machine

In August 2021, the State owned Assets Supervision and Administration Commission emphasized the need to strengthen key core technology research and development for industrial mother machines, high-end chips, new materials, new energy vehicles, etc., and strive to create a "source of original technology". According to the "Made in China 2025 Plan", by 2025, the domestic market share of high-end CNC machine tools and basic manufacturing equipment in China will exceed 80%, and the overall high-end CNC machine tools and basic manufacturing equipment will enter the ranks of world powers.

The development and growth of the manufacturing industry cannot be separated from the "industrial mother machine", and machine tools play a crucial role in China's scientific and technological field. The DaZu machine tool operation team adheres to high quality and high standards, upholds DaZu's excellent genes of "leading, fast, service, and sharing", and outputs high-end products and high-quality services to the industry and users with rigorous and meticulous craftsmanship spirit.